https://www.facebook.com/109674879064727/videos/2922565218072211

Video: Renovated Strela arrives in the new Tatra truck museum

Not less than 22 videos: Moving Tatra trucks from depots and the present museum to the all new truck museum

VIDEO: Moving history. Tatra trucks are heading to the new museum

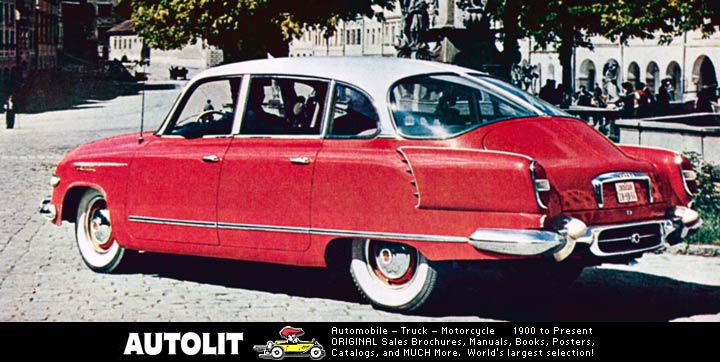

The seventy-year-old Tatra 128 was the first car parked on Tuesday in the large hall of the new Tatra Truck Museum in Kopřivnice. Gradually, more will be added to it in April, from the oldest NW type K car in a firefighting design from 1910 to the current Phoenix model from the current production of the Kopřivnice car manufacturer.

Transport Tatra trucks to the new museum in Kopřivnice | (1:44) | video: iDNES.tv

But people will still wait for the museum to open, it is not planned until this autumn.

“One of the main reasons why this museum was established is that Tatra manufactures trucks, but has nowhere to present them. Some of them were on display in the existing Tatra Kopřivnice Technical Museum, but this does not have sufficient space capacity, “said Lukáš Filip, head of the new museum, which falls under the Museum of the Novojičín Region.

At the turn of 2015 and 2016, a study of the reconstruction of the hall of the former foundry into a new exhibition space was born. At that time, Tatra also bought a part of the private collection of the collector Jiří Hlach, which contained over forty cars from the Kopřivnice car manufacturer.

Together with trucks from the existing Tatra Technical Museum, they thus form the basis of a new exhibition.

“Hlach’s collection contains a number of important historical models, thanks to which we can well capture the typological development of this brand in the new exhibition,” explained Filip.

However, the oldest exhibit will be a carriage, because the founder of the local tradition, Ignác Šustala, started with them.

“Then there was the wagon tradition , but it did not fit us, so we will continue with the oldest trucks from the first decades of the last century. There will be thematic sections: fire trucks, various important types such as 111, 138, 148, 805, which were produced in large quantities, then there will be expedition vehicles or competition cars for the Dakar. We try to capture everything important that is associated with Tatra trucks and their development, “said Filip.

Some of the exhibits had to be restored before the exhibition.

“Somewhere it was a small adjustment, somewhere it was more complicated. It is interesting that most of the Tatra trucks, which were in the technical museum and which have not been driven for decades, managed to start for the first time. It was enough for the men from the factory to come, plug in new flashlights, turn the key and in most cars the engine immediately started, “said Filip.

The extension for visitors will be currently prepared interactive elements. ”Our goal is to follow the standard of European museums of the 21st century so that we can draw visitors deeper into the whole issue through interactive applications,” explained the director of the Museum of the Novojičín Region, Zdeněk Orlita.

For example, people will be able to use their smartphones to learn more about some of the exhibits.

“Thanks to this, it will be possible to look into the interior of cars, for example, which the visitor would not normally get into. The application will thus allow a much more detailed penetration into the exhibit than would be possible in real life. We are able to cover any detail with augmented reality, including, for example, the operation of the engine or the display of construction plans and drawings of cars, “Orlita explained.

We are also waiting for the Slovak Missile

He reminded that the museum will also install a collection of historic motorcycles, which was donated to the region by academic sculptor Miroslav Rybička, a lifelong collector of these machines.

The main investor of the new museum is the Moravian-Silesian Region. ”We took care of the reconstruction of the hall and interior equipment, but most of the exhibits belong to Tatra Trucks, which also takes care of their restoration,” said Lukáš Curylo, Deputy Regional Governor.

The city of Kopřivnice is also involved in the project, which takes care of the construction of access roads and parking lots.

“Originally, we expected the museum to open this spring or early summer. Due to the fact that the development and testing of interactive elements is waiting to be completed, we expect to open it sometime in September, “added Curylo. The budget for the construction of the museum reached almost 173 million crowns, of which 111 million are subsidies from the European Union.

One of the last exhibits that is still awaited is the listed motor train Slovenská strela, which has undergone a complete renovation in the past two and a half years .

“Now tests are underway, which require a range of about 600 kilometers, so that the Slovak missile can be routinely operated on lines in our country and abroad. We are also counting on her trips from the depository on various festive occasions, “said Pavel Lazar, CEO of Tatra Trucks.

VIDEOS:

About the new truck museum: https://www.idnes.cz/ostrava/zpravy/tatra-prevoz-muzeum-nakladnich-automobilu-historie-koprivnice.A210407_602319_ostrava-zpravy_woj

Several trucks on Regional tv broadcast: https://www.facebook.com/watch/?v=220997359616304

Nesselsdorfer Wagenbau’s first truck: https://www.facebook.com/106148391074400/videos/464338264618687

T23 chassis: https://www.facebook.com/muzeumtatra.mnj/videos/755625005150714

T25: https://www.facebook.com/106148391074400/videos/257628372752877

T72: https://www.facebook.com/muzeumtatra.mnj/videos/374620557005772

T85: https://www.facebook.com/muzeumtatra.mnj/videos/3867307050028568

T93: https://www.facebook.com/muzeumtatra.mnj/videos/463650444882507

T111C Fuel truck: https://www.facebook.com/106148391074400/videos/283746629947808

T 138 Kipper: https://www.facebook.com/106148391074400/videos/1082061092285204

T138 Lambarene (Albert Schweitzer) truck: https://www.facebook.com/106148391074400/videos/453457939046036 https://www.facebook.com/106148391074400/videos/501706774321015

T813 Fire truck: https://www.facebook.com/muzeumtatra.mnj/videos/460910828325246

T813 military truck: https://www.facebook.com/muzeumtatra.mnj/videos/1425061851161634

T815: https://www.facebook.com/muzeumtatra.mnj/videos/198632008483609

T813 Kipper: https://www.facebook.com/muzeumtatra.mnj/videos/399542224615213

T500HB Bus: https://www.facebook.com/106148391074400/videos/748525185844254

OT64 armored 8 wheeler: https://www.facebook.com/watch?v=458424922134218

T805: https://www.facebook.com/106148391074400/videos/893969684730271

T805: https://www.facebook.com/106148391074400/videos/288964606091419

T815 GTC Around the world truck: https://www.facebook.com/106148391074400/videos/160210399313924

T815 1988 Paris-Dakar truck: https://www.facebook.com/106148391074400/videos/1205210579912683

Tatra Defense Vehicle unveils first Titus Command and Control vehicle

TATRA TRUCKS delivered 1,186 trucks last year and fulfilled its commitments

Belgian Army buys 879 DAF Trucks with Belgian CF cabins, DAF engines and Tatra chassis

Video: Czechoslovak propaganda film featuring several CS brands and includes T111 and a T603 visiting Telc for a photoshoot on its way to the 1958 Brussels World Fair

TATRA TRUCKS delivered 1,186 trucks last year and fulfilled its commitments

18 January, 2021

Despite the pandemic and worldwide decline in the automotive industry, the Kopřivnice-based Tatra Trucks have achieved their production goals and fulfilled their commitments to customers. In total, they delivered 1,186 trucks to their customers. In 2020, they also celebrated their 170th anniversary and won a major contract in Germany.

In sum, the Kopřivnice truck maker produced 1,181 and sold 1,186 trucks in 2020, out of which almost 60 percent went to exports and over 40 percent to the Czech and Slovak markets. In terms of production, TATRA TRUCKS managed slightly exceed their plans for 2020. “For 2021, TATRA plans a comparable volume of production and sales to that of 2020. We are constantly expanding our portfolio of customers and projects in order to achieve this goal. However, we are also working with the option that customers may postpone some of the projects to a later date due to the epidemic,” said Pavel Lazar, CEO and Chairman of the Board of TATRA TRUCKS.

In 2020, TATRA TRUCKS won new orders together with partner companies and produced some unique vehicles. Above all, there was the delivery of 41 TATRA FORCE 4×4 special fire trucks, with an option for another 5 units for fire brigades of the federal state of Brandenburg, where TATRA TRUCKS cooperates with their long-term partner THT Polička. This is the first such large order for TATRA fire trucks in strongly competitive Germany. Already at the beginning of the year, TATRA TRUCKS cooperated with Excalibur Army and THT Polička to deliver the Fire and Rescue Service of the Czech Republic with two special fire trucks – a tanker-type rugged CZS 15 Triton fire truck and CV 40 large-volume tanker, which are unique in their categories.

In defense technology, representatives of TATRA EXPORT and Huta Stalowa Wola signed an agreement in September of last year at the MSPO defense fair in Kielce, Poland, to offer the Polish Army the TATRA 4×4 armoured vehicle project. Deliveries of TATRA trucks for the Army of the Czech Republic also continued as per contracts signed in previous years. TATRA TRUCKS also announced that they plan to expand in the Brazilian market. In addition to expanding their cooperation with the Brazilian defense industry, a production plant should be constructed directly in Brazil this year to manufactrure TATRA trucks intended primarily for the local civilian market.

2020 was marked by the coronavirus pandemic, which affected a large part of the economy of most countries around the world. The pandemic hit the automotive industry with a particularly hard impact. In this context, the vast majority of car and truck makers in Europe have suspended their production for some time and have had to deal with problems associated with it and with production declines. TATRA TRUCKS in Kopřivnice was one of the few companies that did not stop their production line. It ran at full speed throughout the year even while corporate management introduced strict hygiene and safety measures.

This allowed the truck maker to secure the protection of its employees’ health and at the same time fulfill their commitments to their customers. “Despite not yet presenting our financial results, we can say that our well-established organizational arrangements and mutually friendly cooperation with all business partners have let us not only keep our production going without interruption, but also exceed our business and financial goals projected for 2020,” said Miloslav Mahut, the Finance Director and Deputy Chairman of the Board of Directors of TATRA TRUCKS.

TATRA TRUCKS fulfilled their production plans and deliveries to customers even though they had to face certain difficulties. These arose mainly due to delays in the supply of components from a few subcontractors, where the pandemic and resulting restrictions caused manufacturing complications. The TATRA TRUCKS management solved the problems by regrouping its production plan and setting up a new sequence on the line. We also managed to provide full service and after-sales services to customers. In addition, the company set up a servicing package to support the operation of Tatra trucks used by the Emergency Service of the Czech Republic and the Army of the Czech Republic performing important tasks within the framework of government measures to protect the health of the population.

Last but not least, the previous year was also the 170th year of the Kopřivnice company’s existence. In June, the company commemorated its founding in 1850, when Ignác Šustala started his business. TATRA TRUCKS can thus be proud of the longest continuous tradition of wheeled vehicle production in the world. In December, TATRA commemorated the 198th anniversary of the birth of its founder Ignác Šustala. At the end of the year, a demanding several-year reconstruction of the national cultural monument called “Slovenská strela”, a motorized railway car manufactured by the Kopřivnice company in the 1930s, was also completed. This extraordinary railway car is to return to Kopřivnice in the first quarter of this year, where it will be exhibited in a modern pavilion in front of the new TATRA truck museum.

Several spots of Tatras at the Koprivnice testing grounds and their classic vehicle depot shown at Dutch TV game show.

VIDEO: http://www.npostart.nl/wie-is-de-mol/09-01-2021/AT_2147043 The Tatra part/ Koprivnice part is the second part of the video and starts after 36,5 min.

Indian Army orders High Mobility trucks from BEML for transportation to remote areas

https://www.army-technology.com/news/beml-high-mobility-vehicles-indian-army/

The Indian army – Tatra scam (2012 article) : https://www.rediff.com/news/slide-show/slide-show-1-faq-all-you-wanted-to-know-about-the-army-tatra-scam/20120426.htm

Present relationship between Tatra and BEML (2015 article) https://www.tatratrucks.com/about-the-company/press-and-media/press-releases/tatra-trucks-resumed-cooperation-with-the-indian-state-owned-company-beml/

BEML: https://en.wikipedia.org/wiki/BEML_Limited

Trucks manufactured by BEML (source Wikipedia):

Trucks[edit]

BEML manufactures Czech Tatra trucks and rebadges them under license.[11]

- BEML - TATRA T810 VVNC 6×6

- BEML – TATRA T810 VVL 6×6

- BEML – TATRA T810 VTI 6×6 – Tank Transporter

- BEML - TATRA T815 VVNC 8×8

- BEML – TATRA T815 VVL 8×8

- BEML – TATRA T815 VTI 8×8 – Tank Transporter

- BEML – TATRA Crash Fire Tender

- BEML - TATRA T816 6MWR 8T 10×10

- BEML – TATRA T815 27ET96 28 300 8×8

- BEML – TATRA T815 26RR36 22 255 6×6

- BEML – TATRA T158 PHOENIX VTI 6×6 – Tank Transporter

- BEML – TATRA PHOENIX 8×8, 6×6, 4×4

- BEML – TATRA FORCE 10×10, 8×8, 6×6, 4×4

- BEML – TATRA TERRN°2 10×10, 8×8, 6×6, 4×4

- BEML – TATRA TACTIC 6×6

- BEML Aircraft Towing Tractor

- BEML Armoured Recovery Vehicle WZT

A probe into an alleged scam in the purchase of Tatra trucks for the Indian Army revealed that the Czech company had agreed to supply trucks directly at a lower price in 1994 to BEML without involving the British agent, Tatra Sipox. BEML did not accept the offer then.[12]