https://www.facebook.com/100003579470189/videos/g.522940227833575/949518595844771

Video: Russian T27b runs again

New Dutch Tatra Facebook Page

Een paar weken terug heb ik een Nederlandse Tatra Facebook site gestart over het Tatra gebeuren in Nederland. Inmiddels heeft de pagina al een kleine vijftig leden. Geweldig!

Ik hoop dat iedereen de doelstellingen onderschrijft en “Tatra classic car NL” gebruikt waar voor het bedoeld is: Nederlandse Tatra wetenswaardigheden, Nederlandse artikelen, foto’s van Nederlandse Tatra’s, aankoop- en restauratieverhalen, onderdelen vraag- en aanbod, aankondiging en verslagen van Tatra rallies met Nederlandse deelname enz, zolang er maar een connectie is met NL.

Omdat nogal wat buitenlanders af en toe naar Nederland komen om deel te nemen aan Tatra rallies in Nederland en bijeenkomsten hier een warm hart toedragen, zijn zij ook van harte welkom op deze pagina en kunnen zij in hun eigen taal berichten sturen over aan Nederland gerelateerde onderwerpen inclusief hun eigen ervaringen met het Nederlandse Tatra gebeuren! Zolang het onderwerp maar een Nederlandse connectie hebt, kun je in je eigen taal het bericht posten, eventueel vergezeld door een vertaling in het engels.

Met vriendelijke groet,

Kees Smit

Dear people, A few weeks ago I started a Dutch Tatra Facebook site about the Tatra happening in the Netherlands. The page now has almost fifty members. Awesome!

I hope everyone subscribes to the objectives and uses “Tatra classic car NL” for what it is intended for: Dutch Tatra facts, Dutch articles, photos of Dutch Tatras, purchase and restoration stories, parts supply and demand, announcement and reports of Tatra rallies with Dutch participation, etc., as long as there is a connection with NL.

Because quite a few foreigners occasionally come to the Netherlands to participate in Tatra rallies in the Netherlands and have a warm heart for meetings here, they are also very welcome on this page and can send messages in their own language about Dutch-related topics including their own experiences with the Dutch Tatra! As long as the subject has a Dutch connection, you can post the message in your own language, possibly accompanied by an English translation.

Sincerely, Kees Smit

Liebe Leute,

Vor ein paar Wochen habe ich eine niederländische Tatra-Facebook-Site über die Tatra-Ereignisse in den Niederlanden gestartet. Die Seite hat mittlerweile fast fünfzig Mitglieder. Genial!

Ich hoffe, dass jeder die Ziele unterschreibt und “Tatra-Oldtimer NL” für seinen Zweck verwendet: Fakten über die niederländische Tatra, niederländische Artikel, Fotos der niederländischen Tatra, Kauf- und Restaurierungsgeschichten, Teileangebot und -nachfrage, Ankündigungen und Berichte von Tatra-Rallyes mit niederländischer Beteiligung usw., sofern eine Verbindung zu NL besteht.

Da nicht wenige Ausländer gelegentlich in die Niederlande kommen, um an Tatra-Rallyes in den Niederlanden teilzunehmen und ein warmes Herz für Treffen hier haben, sind sie auch auf dieser Seite herzlich willkommen und können Nachrichten in ihrer eigenen Sprache zu Themen rund um die Niederlande senden … einschließlich ihrer eigenen Erfahrungen mit der niederländischen Tatra! Solange der Betreff einen niederländischen Bezug hat, können Sie die Nachricht in Ihrer eigenen Sprache veröffentlichen, möglicherweise mit einer englischen Übersetzung.

Mit freundlichen Grüßen,

Kees Smit

Vážení, Před několika týdny jsem založil holandskou facebookovou stránku Tatra o tom, jak se Tatra děje v Nizozemsku. Stránka má nyní téměř padesát členů. Skvělý!

Doufám, že se každý přihlásí k plnění cílů a používá „tatranský klasický vůz NL“ k tomu, k čemu je určen: fakta o holandských Tatrách, články o Nizozemích, fotografie holandských Tater, příběhy o nákupu a restaurování, nabídka a poptávka náhradních dílů, oznámení a zprávy o závodech Tatra s holandskou účastí atd., pokud existuje spojení s NL.

Protože do Nizozemska občas přijde poměrně málo cizinců, aby se zúčastnili tatranských shromáždění v Nizozemsku a mají zde srdečné srdce pro setkání, jsou také velmi vítáni na této stránce a mohou zasílat zprávy ve svém vlastním jazyce o tématech souvisejících s Nizozemskem … včetně jejich vlastních zkušeností s holandskými Tatrami! Dokud má subjekt nizozemské připojení, můžete zprávu zveřejnit ve svém vlastním jazyce, případně s doprovodem anglického překladu.

S pozdravem, Kees Smit

A new Tatra model styled in Russia

http://automotivecentury.com/news/this-is-what-a-modern-tatra-might-look-like-how-do-you-like-it/

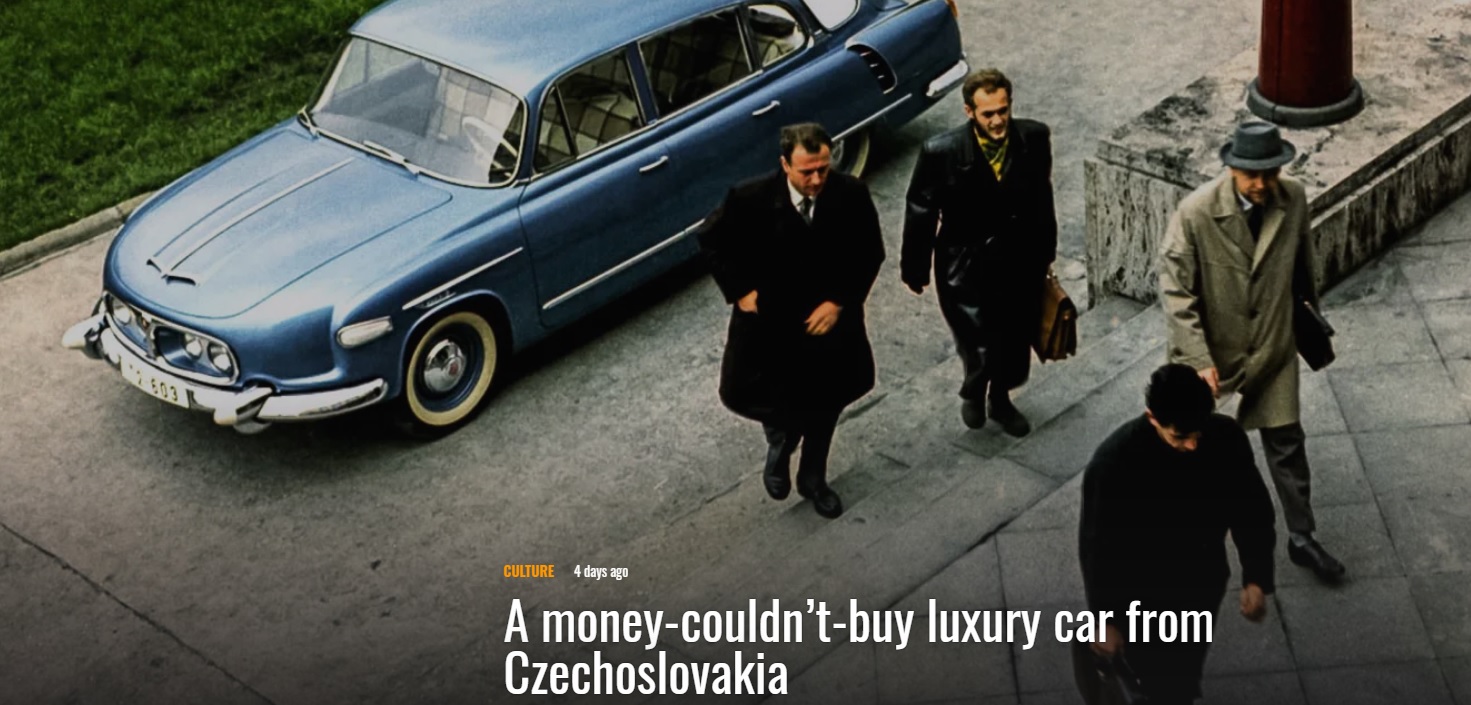

Cars you didn’t know you want

https://www.caradvice.com.au/951881/cars-you-didnt-know-you-want-tatra-603/

Video: Renovated Strela arrives in the new Tatra truck museum

Tatraplan story

Tatra military vehicles of the nineteenthirties and WWII

Not less than 22 videos: Moving Tatra trucks from depots and the present museum to the all new truck museum

VIDEO: Moving history. Tatra trucks are heading to the new museum

The seventy-year-old Tatra 128 was the first car parked on Tuesday in the large hall of the new Tatra Truck Museum in Kopřivnice. Gradually, more will be added to it in April, from the oldest NW type K car in a firefighting design from 1910 to the current Phoenix model from the current production of the Kopřivnice car manufacturer.

Transport Tatra trucks to the new museum in Kopřivnice | (1:44) | video: iDNES.tv

But people will still wait for the museum to open, it is not planned until this autumn.

“One of the main reasons why this museum was established is that Tatra manufactures trucks, but has nowhere to present them. Some of them were on display in the existing Tatra Kopřivnice Technical Museum, but this does not have sufficient space capacity, “said Lukáš Filip, head of the new museum, which falls under the Museum of the Novojičín Region.

At the turn of 2015 and 2016, a study of the reconstruction of the hall of the former foundry into a new exhibition space was born. At that time, Tatra also bought a part of the private collection of the collector Jiří Hlach, which contained over forty cars from the Kopřivnice car manufacturer.

Together with trucks from the existing Tatra Technical Museum, they thus form the basis of a new exhibition.

“Hlach’s collection contains a number of important historical models, thanks to which we can well capture the typological development of this brand in the new exhibition,” explained Filip.

However, the oldest exhibit will be a carriage, because the founder of the local tradition, Ignác Šustala, started with them.

“Then there was the wagon tradition , but it did not fit us, so we will continue with the oldest trucks from the first decades of the last century. There will be thematic sections: fire trucks, various important types such as 111, 138, 148, 805, which were produced in large quantities, then there will be expedition vehicles or competition cars for the Dakar. We try to capture everything important that is associated with Tatra trucks and their development, “said Filip.

Some of the exhibits had to be restored before the exhibition.

“Somewhere it was a small adjustment, somewhere it was more complicated. It is interesting that most of the Tatra trucks, which were in the technical museum and which have not been driven for decades, managed to start for the first time. It was enough for the men from the factory to come, plug in new flashlights, turn the key and in most cars the engine immediately started, “said Filip.

The extension for visitors will be currently prepared interactive elements. ”Our goal is to follow the standard of European museums of the 21st century so that we can draw visitors deeper into the whole issue through interactive applications,” explained the director of the Museum of the Novojičín Region, Zdeněk Orlita.

For example, people will be able to use their smartphones to learn more about some of the exhibits.

“Thanks to this, it will be possible to look into the interior of cars, for example, which the visitor would not normally get into. The application will thus allow a much more detailed penetration into the exhibit than would be possible in real life. We are able to cover any detail with augmented reality, including, for example, the operation of the engine or the display of construction plans and drawings of cars, “Orlita explained.

We are also waiting for the Slovak Missile

He reminded that the museum will also install a collection of historic motorcycles, which was donated to the region by academic sculptor Miroslav Rybička, a lifelong collector of these machines.

The main investor of the new museum is the Moravian-Silesian Region. ”We took care of the reconstruction of the hall and interior equipment, but most of the exhibits belong to Tatra Trucks, which also takes care of their restoration,” said Lukáš Curylo, Deputy Regional Governor.

The city of Kopřivnice is also involved in the project, which takes care of the construction of access roads and parking lots.

“Originally, we expected the museum to open this spring or early summer. Due to the fact that the development and testing of interactive elements is waiting to be completed, we expect to open it sometime in September, “added Curylo. The budget for the construction of the museum reached almost 173 million crowns, of which 111 million are subsidies from the European Union.

One of the last exhibits that is still awaited is the listed motor train Slovenská strela, which has undergone a complete renovation in the past two and a half years .

“Now tests are underway, which require a range of about 600 kilometers, so that the Slovak missile can be routinely operated on lines in our country and abroad. We are also counting on her trips from the depository on various festive occasions, “said Pavel Lazar, CEO of Tatra Trucks.

VIDEOS:

About the new truck museum: https://www.idnes.cz/ostrava/zpravy/tatra-prevoz-muzeum-nakladnich-automobilu-historie-koprivnice.A210407_602319_ostrava-zpravy_woj

Several trucks on Regional tv broadcast: https://www.facebook.com/watch/?v=220997359616304

Nesselsdorfer Wagenbau’s first truck: https://www.facebook.com/106148391074400/videos/464338264618687

T23 chassis: https://www.facebook.com/muzeumtatra.mnj/videos/755625005150714

T25: https://www.facebook.com/106148391074400/videos/257628372752877

T72: https://www.facebook.com/muzeumtatra.mnj/videos/374620557005772

T85: https://www.facebook.com/muzeumtatra.mnj/videos/3867307050028568

T93: https://www.facebook.com/muzeumtatra.mnj/videos/463650444882507

T111C Fuel truck: https://www.facebook.com/106148391074400/videos/283746629947808

T 138 Kipper: https://www.facebook.com/106148391074400/videos/1082061092285204

T138 Lambarene (Albert Schweitzer) truck: https://www.facebook.com/106148391074400/videos/453457939046036 https://www.facebook.com/106148391074400/videos/501706774321015

T813 Fire truck: https://www.facebook.com/muzeumtatra.mnj/videos/460910828325246

T813 military truck: https://www.facebook.com/muzeumtatra.mnj/videos/1425061851161634

T815: https://www.facebook.com/muzeumtatra.mnj/videos/198632008483609

T813 Kipper: https://www.facebook.com/muzeumtatra.mnj/videos/399542224615213

T500HB Bus: https://www.facebook.com/106148391074400/videos/748525185844254

OT64 armored 8 wheeler: https://www.facebook.com/watch?v=458424922134218

T805: https://www.facebook.com/106148391074400/videos/893969684730271

T805: https://www.facebook.com/106148391074400/videos/288964606091419

T815 GTC Around the world truck: https://www.facebook.com/106148391074400/videos/160210399313924

T815 1988 Paris-Dakar truck: https://www.facebook.com/106148391074400/videos/1205210579912683

German T 12 Videos & photos

Found on the Oldtimer Markt Facebook fan pages by Josef Krümpelbeck:

https://www.facebook.com/Oldtimer.Markt.Fans

Please visit the messages of April 8th and 9th.